|

TEKWELL Machinery Co., Ltd

|

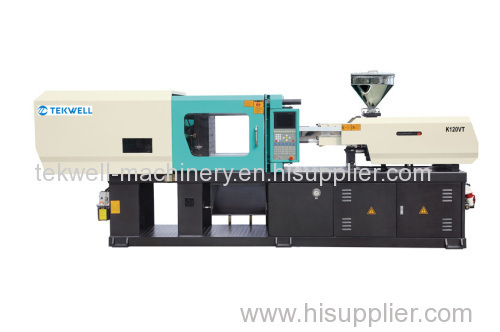

260 ton energy saving injection molding machine

| Payment Terms: | T/T |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

VT series injection molding machine is variable displacement pump injection molding machine

S series is servo motor injection molding machine

VT series injection molding machine

1. Clamping Unit

1.1 The box-board type structure is designed by finite element analysis, which ensures even stress, less deformation, high precision clamping and good rigidity.

1.2 Optimized design of tie bard ensures stable and speedy movement with less impact.

1.3 Lengthened opening stroke, maximum mold height and distance between ties bar for more flexible options of mold.

1.4 Automatic lubrication system. There is lubricating point for everywhere that is easy-abrasion. Good lubrication efficiency will improve/prolong the life time for clamping mechanism.

1.5 Speedy differential clamping function satisfies special movement requirement. High speed clamping shorts cycle time.

1.6 Low pressure mold protection

1.7 Multi ejector mode. Two stage ejection

1.8 Transducer for more precise clamping and ejection position control.

1.9 Copper sleeve instead of aluminum sleeve and steel sleeve on the market.

2. Injection unit

2.1 Twin carriage cylinders ensure more even and stable injection(standard feature for below K200VT/S and K200VT/S)

2.2 Movable Hopper slide, easy for cleaning

2.3 Fast response injection and sealing structure

2.4 one-piece injection unit support

2.5 Nozzle temperature controlled by PID or percentage for easy processing.

2.6 5 stage injection, 3 stage pressuring holding, 3 stage plasticizing control meet different production requirement

2.7 Precise material temperature control ensures production quality.

2.8 Nitriding screw and barrel, good for anti-rust.

2.9 Multi screw is optional

2.10 HUAYE screw

2.11 It's okay to help client to buy hopper dryer

3. Power system

3.1 Fast speed: adoption Japan's YUKEN variable displacement pump, output capacity is 15%~20% higher than the fixed displacement pump with same capacity.

3.2 Power saving: can save power consumption by 25%~70%.

3.3 Environment-friendly: cooling water need is 40%~60% of fixed variable displacement pump because of no overflow heating. High purified hydraulic oil can be used as long as five years.

3.4 Reliable: Life time of seal part can be prolonged dramatically due to the lower oil temperature and special cleaning system of hydraulic oil.

3.5 Low noise disturbance: compact hydraulic design enables more stable and peaceful machine operation.

Specification

shot weight(ps):A.552g B.800g C.1085g

screw diameter(mm):A.50 B. 60 C.70

injection pressure(Mpa):A.232 B.161 C.118

screw L/D ratio: A.25:1 B.20.5:1 C. 18:1

screw stroke(mm): 300

screw speed(rpm): 0-170

clamping force(KN):2600

opening stroke(mm):520

platen size(mmxmm): 835x835

space between tie bars(mmxmm):580x580

max.dalight(mm): 1120

mold thickness(min-max): 195-600mm

hydraulic ejection force(KN):77

hydraulic ejection stroke(mm): 180

ejector pin: 8+1

hydraulic system pressure(Mpa): 17.5

Pump motor(KW): 22

heating capacity(KW):14.5

number of temp control zones: 6

oil tank capacity(L): 435

machine dimensions(mxmxm): 6.1x1.3x2.2

machine weight(kg): 10000